Ettlingenweier

Mechanical Manufacturing at GLÖTZL GmbH

Ettlingenweier – the new production site for mechanical manufacturing at GLÖTZL.

Since January 2025, mechanical manufacturing parts have been produced at our new facility in Ettlingenweier, a district of Ettlingen. Final assembly continues to take place at our headquarters on Forlenweg in Rheinstetten. The close proximity of both locations ensures an efficient and rapid supply of components for final production.

Our new mechanical manufacturing facility spans 1,000 m² across two floors.

Ground Floor

- CNC production line

- Mechanical single-part manufacturing

- Cleaning & deburring

- Cutting & sawing

- Measuring equipment monitoring

Upper Floor

- Work preparation & process control

- Development of mechanical components

- Central storage for mechanical components

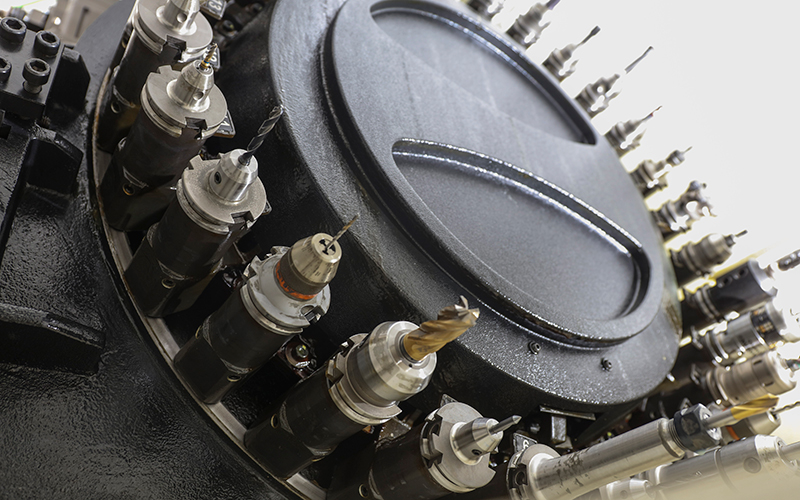

CNC Production Line

With the investment in an additional state-of-the-art CNC lathe, we are preparing our production line for the future.

In addition to a process-optimized arrangement of individual CNC machines, the use of the latest IT technologies for production control ensures highly efficient workflows.

From the creation of manufacturing drawings to machine programming, the entire workflow is seamlessly networked and fully digitalized.

MAZAK QTE 300 – New addition as of 01/2025

CNC Turning and Milling Machines

MAZAK QTN 200 MSY and VCF530

CNC Production Hall

Complete Machinery Park

Single-Part Production

Small series, custom manufacturing, and custom made solutions

Small series

Manual Machinery Park

Custom made solutions

Central Warehouse

Ettlingenweier

Central Warehouse

The storage of all components is fully digitized.

Transparency in inventory, fast part supply, and high-quality assurance define our warehouse management.

Automated Deburring

Finishing

The finishing of our mechanical components is carried out efficiently and quickly using specialized machines.

Cleaning Process

Measuring Equipment Inspection

To ensure the high manufacturing standard of our mechanical components, measuring equipment for quality assurance is inspected annually in accordance with the requirements of DIN ISO 9001:2015.

Industry 4.0 at GLÖTZL

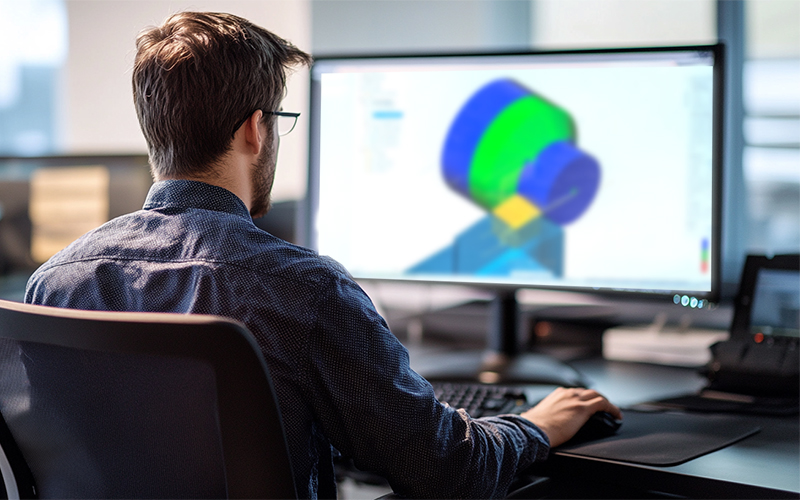

CIM (Computer-Integrated Manufacturing)

We have aligned our production with Industry 4.0, focusing on the intelligent networking of machines and processes using specialized information and communication technologies.

Instead of traditional drawings, the NC programs for the parts to be produced are created directly based on the CAD data generated on the computer. Our CAM system (Computer-Aided Manufacturing) knows the optimal procedures and steps and automatically suggests them for the most efficient manufacturing process. Specifically, this means that the geometry data for the raw part, finished part, and clamping device is imported from the CAD system into the CAM system. The implementation of the CAM system is a key component of our computer-integrated manufacturing (CIM).

3D CAD Data

for NC Programs

Intelligent Networking

of Machines and Processes

RFID Tool Management

Intelligent Tools

Kontakt

So erreichen Sie uns

GLÖTZL Gesellschaft für Baumesstechnik mbH,

Ettlingenweier

Eisenstockstraße 10 I 76275 Ettlingenweier I Germany

Telefon +49 721 5166-0 I Telefax +49 721 5166-30

info@gloetzl.com I www.gloetzl.com

Betriebszeiten

Montag bis Donnerstag

8:00 Uhr bis 16:30 Uhr

Freitag

8:00 Uhr bis 14:00 Uhr